We are constantly in awe of technology. Thanks to the advancements in technology, we can not only just enjoy the online world, looking up jackpot-promo-code.co.uk or various sites that we can have fun on, but also enjoy in the material world that has started to improve. This tech advancement has “hit” all fields and industries, so we aren’t surprised that there have been advancements in the field of architecture as well.

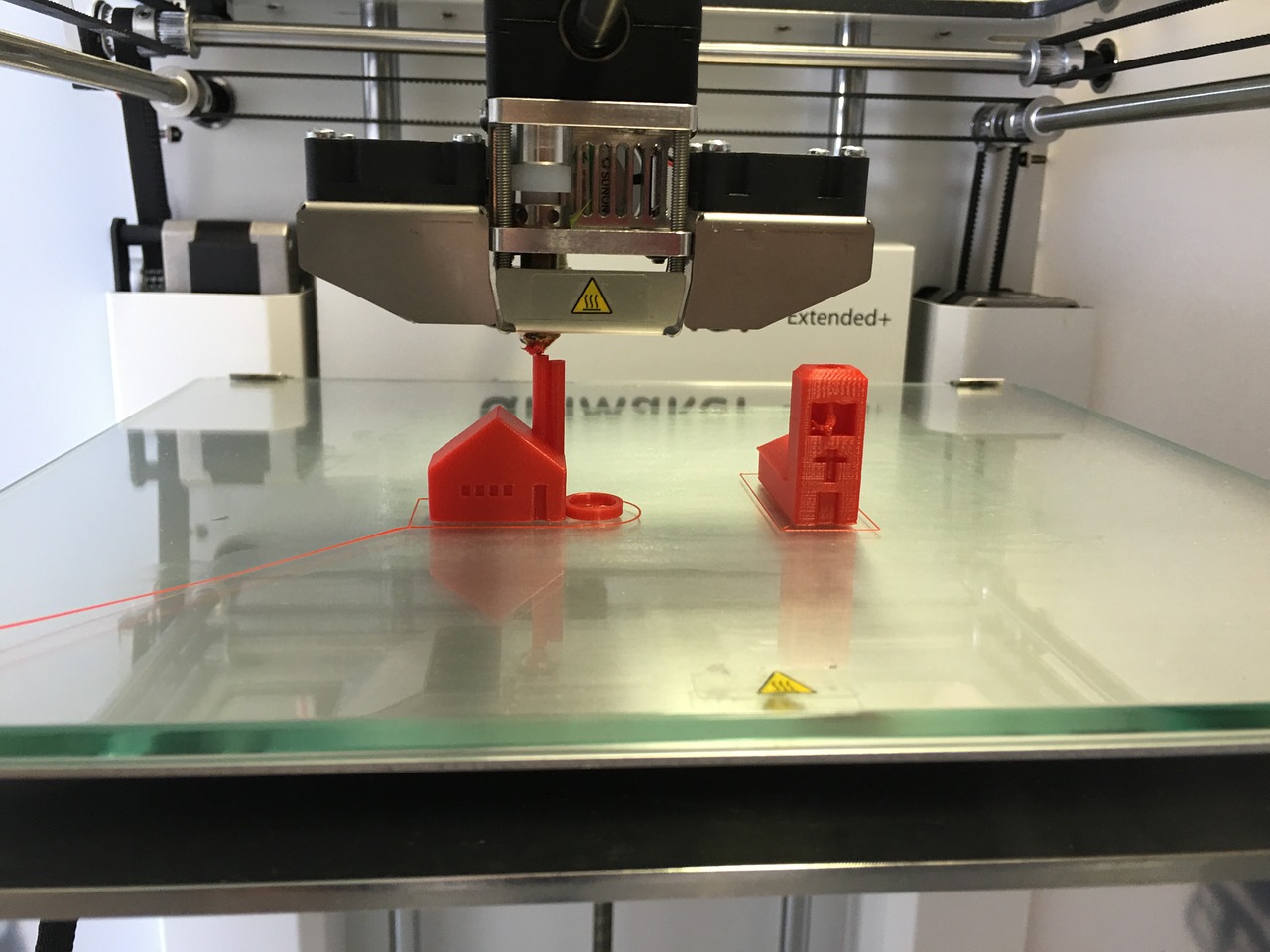

The constant pursuit of more efficient ways of building homes and structures has led to the possible use of 3D printing in the construction sector. Of course, 3D printers have been used for a while now and showed exceedingly good results with miniature works and items, but it is a whole other level of trying to construct a large scale project such is one’s home.

The most significant breakthrough occurred with the development of a 3D concrete printer capable of printing large concrete slabs which are undeniably necessary if you are to make your home with materials capable of withstanding natural occurrences.

This recent advancement paved the way for many companies around the world competing for a shot at creating completely 3D printed houses, and many have already done so and were able to construct 3D printed homes.

This article will give you more insight into the 3D printing of a home and the characteristics of such type of construction. Read on!

Why 3D Printed Homes?

One of the most significant advantages of 3D house printing is the cost of production. Namely, 3D printing involves using biodegradable and recycled materials which reduce the use of new materials in producing feedstocks — the materials actually printed to create the final products.

Also, 3D printing can produce up to 30 percent less material waste, which means less energy and fewer resources will be used. This leads to better and more environmentally friendly ways of building with less CO2 emissions.

An example when even biodegradable materials were used in building 3D printed houses is the Gaia House from WASP — 3D-printing technology developer. This company constructed a house using natural materials such as soil and mud, and waste materials from rice production such as chopped straw and rice husks. The construction is supported with timber beams, and the producers say it would completely biodegrade if not maintained, getting into the original state. Furthermore, since the design can be 3D printed at the spot, there is no need to hire construction companies.

How Does 3D Home Printing Work?

These concreted 3D printers used in production have to be substantial in size, and that is a fact. However, they are still movable so that you can operate them on the spot. The printable feedstock is made from a mixture of materials, soil, sand, stone, clay, and cement to bind the mixture. Then, additives are added to allow concrete to maintain the shape and settle faster. However, the foundation is needed before applying the 3D printing, and it marks the very first step.

What follows is the depositing of specially designed rails to hold the printer, and that, together with the pillars, form the 3D design. Then, the nozzle and robotic arm are connected to the printer, and these are, in turn, connected to the concrete truck as the source of concrete via a big hose.

Frames and reinforcements are also used to make the walls even stronger and to allow the implementation of electrical installations and other non-printed aspects, such as doors and windows.

The mixture is then poured to fill the design and ultimately construct the 3D house.

Conclusion

Although 3D house printing is possible, it would take years before it gets widely used. However, the cost-effective and environmentally friendly nature of this way of building has excellent advantages and sets a proper foundation for future housing development projects that shouldn’t be overlooked.